When you expand to multiple warehouses or inventory locations, your challenges and risks begin to multiply. To get off on the right foot with data hygiene, invest in good systems and follow the correct steps to implement them. Automation and efficient manufacturing accounting implementation will reduce the number of human errors and the likelihood of other issues arising in the future. Increase your desired income on your desired schedule by using Taxfyle’s platform to pick up tax filing, consultation, and bookkeeping jobs.

Reporting capabilities

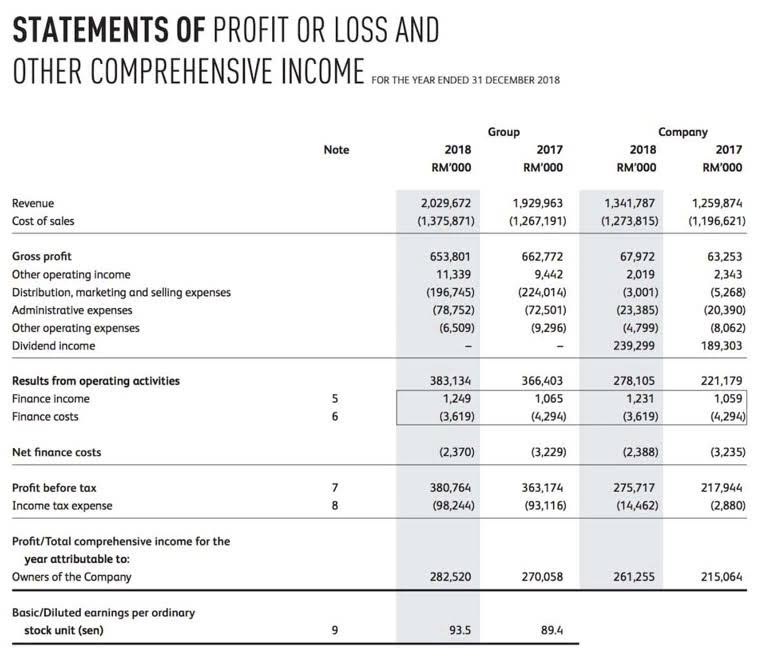

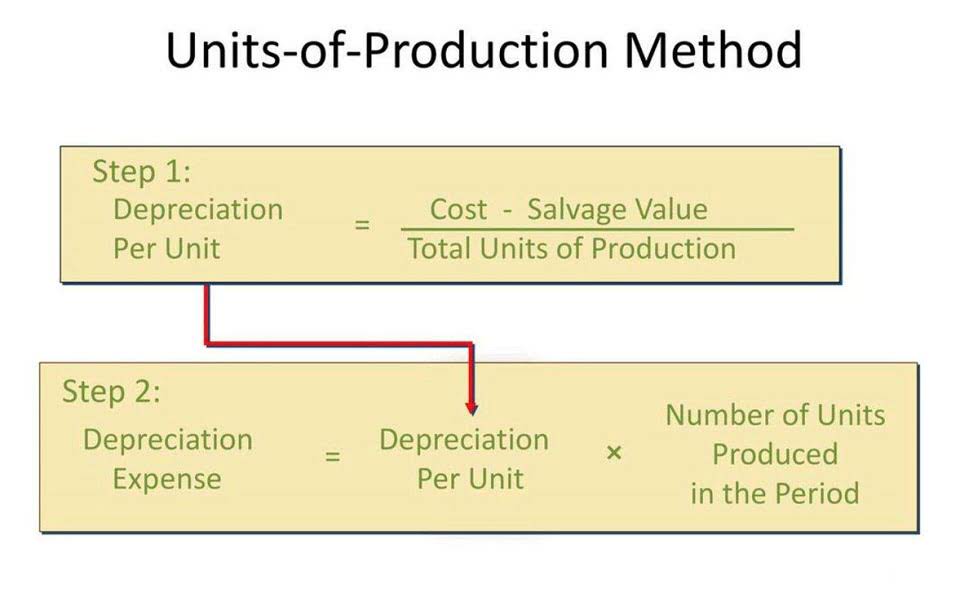

The chosen accounting method should offer detailed insights into material costs, direct and indirect labor costs, and overhead, enabling accurate financial reporting and decision-making. Standard costing is one of the most common production costing methods among manufacturers. It involves calculating a standard rate for groups of costs that go into each unit, including direct materials, direct labor, and manufacturing overhead. This form of accounting in a manufacturing business primarily focuses on providing pointed information to the managerial staff to allow them to decide on core issues and matters regarding the manufacturing process and costs. Manufacturing accounting involves tracking the cost of goods sold, production costs, the efficiency of the manufacturing process, and the margin of profit.

How is WIP calculated?

- Ideally, data should move freely between production lines and the back office, meaning you have accurate real-time data.

- Once the product has moved past WIP, it is classified as a finished goods inventory.

- These costs must be correctly allocated to the right job or product or order, and manufacturing accounting software might be a big help.

- All information prepared on this site is for informational purposes only, and should not be relied on for legal, tax or accounting advice.

It offers 17 modules, including finance, sales, inventory management, manufacturing and purchasing modules. Using its manufacturing modules, you can automate your manufacturing processes, track revisions, track and forecast resources and manage your shop floor and warehouse. Producing credible financial track records helps businesses reinforce investor faith and build a reputation for honesty. Auditing allows a manufacturing business to ensure that the accounting processes and standards deployed in analyzing a company’s finances are up to the mark. This helps entrepreneurs rest assured that their firm’s statements and records, and in turn the company’s adherence to business ethics and integrity.

- To help improve and ease accounting for manufacturing, here are 5 best practices for inventory and production cost accounting methods.

- Some manufacturing companies prefer to transfer finished goods from the factory to the warehouse at an increased price, by adding a pre-set margin (called the manufacturing profit) to the production cost.

- Work-in-process (WIP) or work-in-progress inventory refers to products that have made it through part of the manufacturing process but remain unfinished.

- This is a costing method that differs from job costing in that it incorporates more indirect costs, such as resource consumption.

- Variable costs, on the other hand, can include assembly line workers whose roles change as you produce higher volumes.

Direct Labor Manufacturing Account

Inventory valuation, direct labor and manufacturing overhead costs are just part of the recipe that is cost accounting in the manufacturing industry. This article explains what manufacturing accounting is, the types of manufacturing costs that must be accounted for, and how to accurately value production costs using different methods and technologies. It involves tracking the costs for every item you produce, including direct materials, direct labor, and manufacturing overhead. We recommend using software that is well integrated with the overall production and inventory management solution of choice. This ensures seamless data movement between the shopfloor, inventory, and the back office, and further simplifies managing your business.

Nick Gallo is a Certified Public Accountant and content marketer for the financial industry. He has been an auditor of international companies and a tax strategist for real estate investors. He now writes articles on personal and corporate finance, accounting and tax matters, and entrepreneurship. This approach is primarily beneficial for manufacturers who produce a relatively low number of unique products. For example, a manufacturer of made-to-order furniture would likely employ job costing.

Modules Included

Complex manufacturing processes can make it difficult to track and pinpoint costs, and allocating indirect costs correctly can be a guessing game. It is the responsibility of the Accounting Department to address these challenges. Accurate manufacturing accounting ensures businesses can confidently sail through financial uncertainties, thanks to comprehensive accounting data.

- When you leave a comment on this article, please note that if approved, it will be publicly available and visible at the bottom of the article on this blog.

- It also allows you to track where your inventory is in real time while maintaining a database of suppliers you can turn to when inventory is needed, complete with your purchase history for easy reordering.

- Running a manufacturing company while managing its books is a challenging prospect.

- Goods are transferred to the trading account at a value which the business would have paid had these goods been bought from other manufacturers.

- Here are brief explanations of some fundamental terms you’ll need to know to succeed.

- This is vital for producing accurate financial statements and making informed decisions.

- The accounting for a manufacturing business deals with inventory valuation and the cost of goods sold.

An automated inventory management system facilitates accurate inventory accounting and can greatly reduce the time and cost required to manage physical stock. You need accurate financials to correctly forecast cash flow and ensure you’re paying the right amount of taxes. And the efficiency with which you perform accounting for manufacturing directly impacts your bottom line. https://www.bookstime.com/ software helps you track your financials in real time using cloud-based technology and multi-platform integrations. This can result in drastically different figures for your business financials, which is why it’s important to use the right approach based on your specific business requirements.

- Offering a selection of experienced editors, graphic artists, and everything in between, we are here to handle all of your staffing needs.

- In addition, you can scale up your system’s performance to process more transactions as you and your partners need.

- Royale Staffing delivers the most knowledgeable IT professionals to maintain your systems and enable you to achieve your company’s goals faster and more efficiently.

- Rootstock has purpose-built features for real-time inventory management for manufacturers.

- This method is preferred by manufacturing businesses due to the ability of cost accountants to track the exact production costs involved, allowing them to arrive at an accurate price quote.

- However, there’s an exception for small businesses with less than $26 million in average annual revenues.

Create a Project Plan